- HOME

- Company

- Products

- Solutions

- Latest Post

- FAQ&Service

- Contact Us

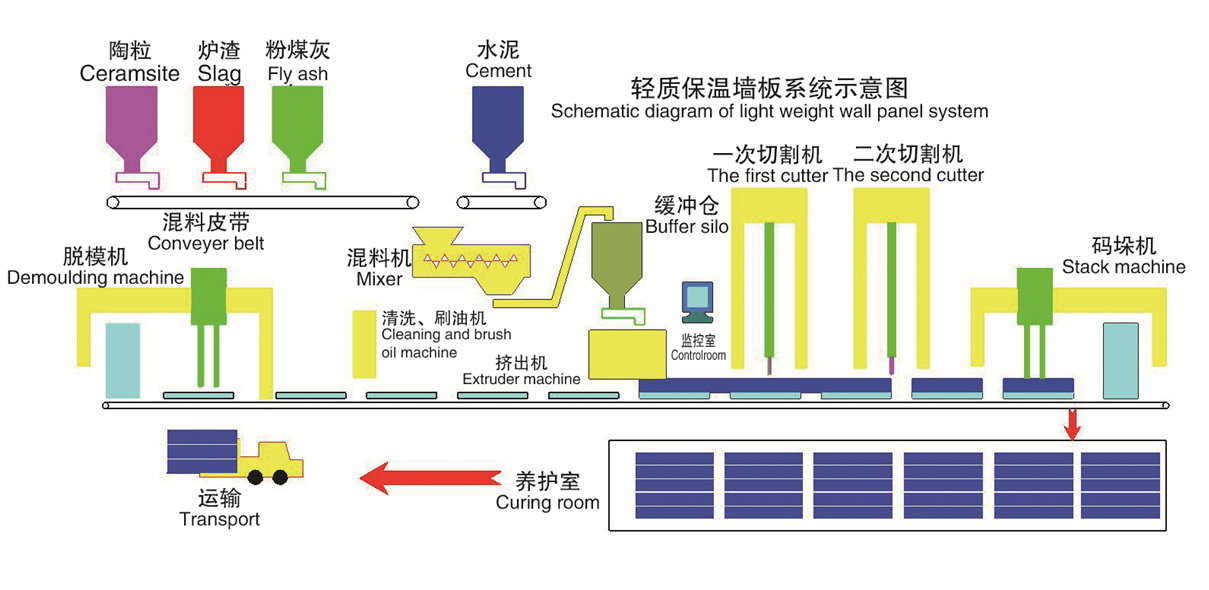

Full Automatic Lightweight Wall Panel Production Line:

Light weight wall panel have the following advantages: light weight, high strength, sound insulation, heat insulation, damppoof, fireproof, smooth surface, easy to transport, easy to install, beautiful appearance, accurate size, stable quality, share the bearing load, reduce the idth of the foundation, increase utility area, shorten the construction period, improve the efficiency of construction. It is widely used as filled wall in frame

structure, shear wall structure, steel structure and other forms.

The designed capacity of this production line is 400000m2. The main machine is fixed. The wall panel has high density and smooth surface because the material have been extrusion, vibrate at the same time by side plate, core-mould. After forming slab, adopts steel plate support to process initial maintenance. Wall panel is

convenient to move, flexible in construction site, high utilization efficiency. The transmission device driven the supporting plate move; The spiral variable frequency speed regulation control the forming slab process; The central control unit control the density of the slab to realize continuous automatic produce. As we chose low water cement ratio dry concrete to form the slab, so the density and strength of the hollow core wall panel is very high. The water cement ratio is 0.3-0.4; The slumps is 0; The dry shrinkage rate<0.03%. It

has avoided the shrinkage cracks problem in application of lightweight wall panel. Automatic continuous production, high efficiency, high quality consistency, these features have make sure the quality of wall panel.

The main advantages of lightweight wall panel:

1. Green environmental protection: The raw material is industrial waste residue after high temperature smelting (water slag, fly ash, slag, ceramic) ; cementing material is ordinary portland cement. All the product is inorganic, harmless to the human body and environment. It belongs to a new environmental protection

material which has no pollution and emission in the process.

2. Lightweight: The weight of 90mm thickness slab is no more than 80kg/m2. About 50%

weight less than the traditional use of soild clay brick and lime sand brick.

3. High strength: compression strength>5MPa

5. small shrinkage:Drying shrinkage value≤0.6mm/m

6. Heat and sound insulation: 90mm*600mm*2800mm,7 holes, hole rate is 34%. So it have good heat and

sound insulation.

7. Fire proof and dampproof: Adopt cement as cementing material, which is an hydraulic material. It has good hydrolytic resistance, not jump the shell and non-scale. It is also a fire proof material with high

fire resistance limit.

8. Zero radioactivity:Radiation performance index is far below the national standard.

9. High efficient in construction: qualitative module width, highly customized, special size field cutting, splicing assembly construction; cutting, drilling and make hole is available, no need of powder

sand ash, conveniently to set pipeline; shorten the construction time, saving cycle cost.

10. Significant economic benefits: The biggest advantage of this product is light weight which can reduce the overall load of buildings, to reduce construction cost.

11. Reduce wall occupied area, increase the use space: the use area of residential can save 3.4-4m2 for each 100m2.

Application:

Consists of this production line:

This producing line mainly consists of following parts: special mould, automatic batching, sealing and conveying, continuous dry mixing, wet mixing, automatic move of plate, material conveyor, continuous extrusion, molding control, servo synchronous tracking, automatic cutter, analysis of online visual quality, automatic stacking, forklift operation, automatic maintenance, temperature and humidity control, automatic demoulding, the central control computer system,etc.

The main parameter of full automatic wall panel production line:

Main parameter item

Parameter

Production line index

Machine weight

45000kg

Installed capacity

140kw

Length

40m

Width

20m

Height

4.5m

Control system

PLC automatic control

Extruder speed

Average 1.8-2.5m/min

Productivity

Annual

360000㎡

Average power of continuous produce

≦80kw

Output slab speed

Max 2.3m/min

Single-class workers

6-8 people

Productivity each hour

70㎡/h

Annual output for each class

150000㎡

Output wall slab type

Length:2.4-3.3m

Width:600mm

Thickness:90mm、120mm、150mm

Raw material

Water slag,fly ash, slag,

tailing residue, construction waste.

Cementing material

Ordinary Portland cement

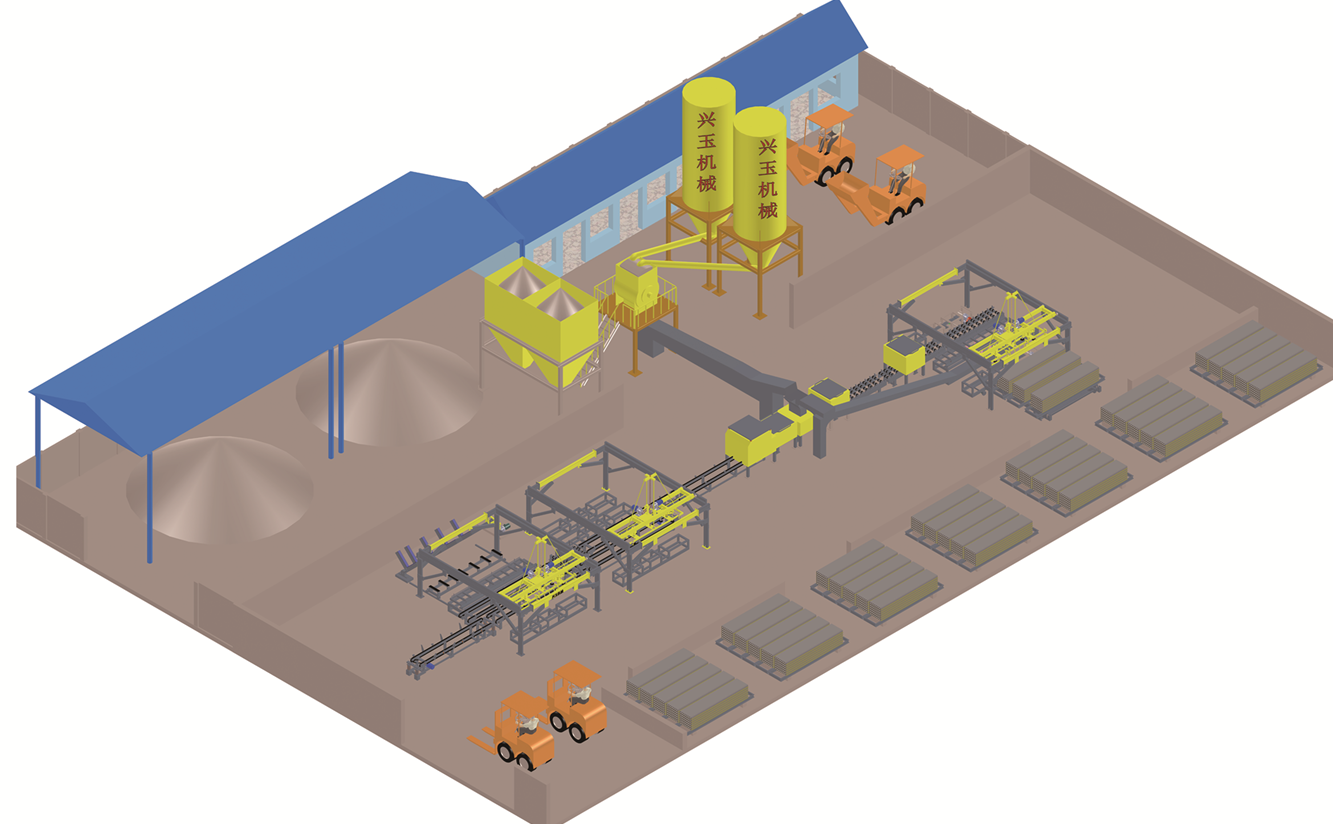

The full automatic wall panel factory layout:

The producing flow of this production line: